First published as article on LinkedIn

Download the article as PDF here: NEW! Advanced Automotive Electrical Testing with RTStand LV124 LV148 (PDF, 1.2MB) (english)

INTRODUCTION

In the competitive automotive industry, ensuring that electronic components meet stringent standards is crucial. The RTStand LV124 / LV148 testing system by WKS Informatik GmbH stands at the forefront of automotive testing technology, providing unparalleled precision and efficiency. This article explores the benefits of the RTStand LV124 / LV148 system, its compliance with various automotive standards, and how it supports automated testing to meet and exceed industry requirements.

WHAT ARE LV124 AND LV148 ?

LV124 and LV148 are umbrella terms for all norms concerning 12V, 24V and 48V architectures respectively. Also, they are namesake for our family of fully automated testing systems.

The standards and specifications, which run under this LV124 and LV148 umbrella, specify the requirements, test conditions, tests for electrical, electronic and mechatronic components and systems to be used in vehicles with 12V, 24V and 48V systems.

The first drafts were done by representatives of a wide range of automotive manufacturers (OEMs) such as Audi, Volkswagen, BMW, Porsche, Mercedes-Benz, etc. Those tests are included in their current in-house OEM specifications under various names (e.g. VW 80000, MBN LV124, BMW GS 95024-3-1, etc.).

These standards are used to check the quality and safety of components.

One example of components are outer and interior lights, battery management systems, Lidars, radars, pumps, cooling/heating systems, intelligent computers, displays, infotainment devices, etc.

RTStand LV124 / LV148 is built specifically for the electrical tests of the LV124 / LV148 standards. Having a generic and scalable design it can supports tests for all the types of components mentioned above.

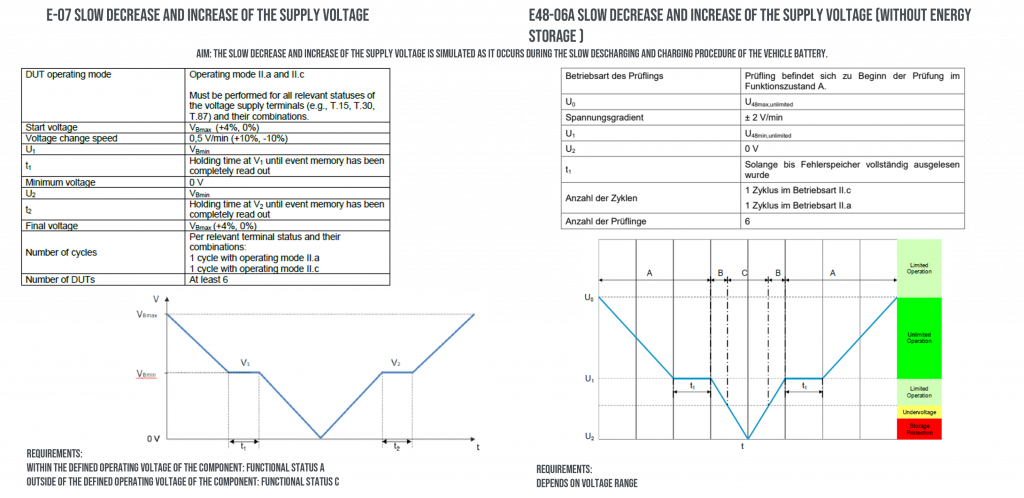

Figure 1. LV124 and LV148 test case comparison, e.g. slow decrease and increase of the supply voltage

ADVANTAGES OF RTSTAND LV124 / LV148

High Precision and Reliability

The RTStand LV124 / LV148 system is designed to deliver precise and reliable testing results, ensuring automotive components meet the stringent requirements of LV124 and LV148 standards. This precision is critical for components subjected to various electrical conditions, ensuring their robustness and longevity. All voltage and current measurements are within the required 2% of the norms, even reaching under 1%. Moreover, the measurement units are delivered Dakks calibrated, according to the highest German calibration standard, to meet the ISO 17025 standards.

Comprehensive Automation

Automation is at the core of RTStand LV124 / LV148, significantly reducing manual intervention and the associated risks of human error. Automated testing ensures consistency, repeatability, and high throughput, which are essential for meeting tight development cycles in the automotive industry.

Reduced Testing Time

The advanced automation and integration capabilities of RTStand LV124 / LV148 drastically cut down testing times. This acceleration in the testing process helps automotive manufacturers bring their products to market faster, providing a competitive edge. RTStand LV124 / LV148 achieves 75% faster testing through automated test execution, automated measurements, automated switching of operation modes, and control of multiple climate chambers from various manufacturers.

Cost Efficiency

By minimizing manual testing efforts and reducing the need for multiple test setups, RTStand LV124 / LV148 helps lower overall testing costs. The system’s automated features also lead to lower maintenance costs and reduced downtime, further enhancing cost efficiency. Thus, break-even against external test labs can easily be reached within a year.

Figure 2. RTStand LV124 / LV148 fully automated testing system

COMPLIANCE WITH AUTOMOTIVE STANDARDS

Supported Standards and Specifications

RTStand LV124 / LV148 supports a broad range of automotive standards, ensuring comprehensive compliance for various testing requirements. These include, but are not limited to:

- VW80000 (2013, 2017, 2021): The most known standard for Volkswagen components.

- ISO16750-12V (2012, 2023): International standard for environmental conditions and testing for electrical and electronic equipment in road vehicles for 12V systems.

- ISO16750-24V (2012, 2023): International standard for environmental conditions and testing for electrical and electronic equipment in road vehicles for 24V systems.

- ISO21780 (2020): International standard for environmental conditions and testing for electrical and electronic equipment in road vehicles for 48V systems.

- BMW GS95024-2-1 (2010, 2011, 2021): BMW’s specific standard for electrical/electronic components.

- KTMT201T202 (2023): KTM BMS specification.

- HyundaiHKMC_ES95400-10 (2015, 2022): Hyundai standard for electrical/electronic components.

- MAN3499-2-12V (2017, 2020): Standards for MAN Truck & Bus components operating at 12V.

- MAN3499-2-24V (2017, 2020): Standards for MAN Truck & Bus components operating at 24V.

- MBN10567 (2018): The newer standard for electrical and electronic components in vehicles Mercedes-Benz components.

- MBN LV124 (2013): The standard for electrical and electronic components in vehicles.

- McLaren MSL03040004 (2012): McLaren’s standard for vehicle components.

- PSA B217110 (2019): Standard for PSA Group components.

- Tesla TS-0000425-05 (2022): Tesla’s stringent testing requirements for various voltage systems, 12V, 24V and 48V.

- Volvo LAH33721792 (2022): Volvo’s testing requirements.

- GMW 3172 (2018): General Motors’ standard for electrical/electronic components.

- FCA CS00054 (2018): Standard for FCA (Fiat Chrysler Automobiles) components.

- AUDI LAH4N0419091 (2021): Audi’s standard for electrical/electronic components.

- BMW BT Tests (2023): BMW’s additional testing requirements.

- BMW NCAR (2023): BMW’s specification for specific products.

- Lucid EEDRCS (2023): Lucid Motors’ standard for electrical testing.

- AUDI LAH895941 (2023): Audi’s additional specification for testing.

- BMW GS95024-2-1 ISELED (2010): BMW’s specific requirements for ISELED components.

- VW82148 (2013): Volkswagen’s standards for electrical components in 48V systems.

Etc.

The RTStand LV124 / LV148 system supports detailed testing protocols for various norms, ensuring components’ robustness under different conditions. The norms listed above all include tests like:

- Long-time overvoltage and undervoltage

- Transient overvoltage and undervoltage

- Jumpstart and load dump scenarios

- Superimposed voltages

- Slow and fast supply voltage changes

- Microseconds short interruptions

- Reverse polarity, ground offset and backfeed tests

- Sleep current tests

- Short-circuits

- Synchronized switching of several terminals

Moreover, the software’s flexibility allows customers to define their own waveform pulses and create customized norms.

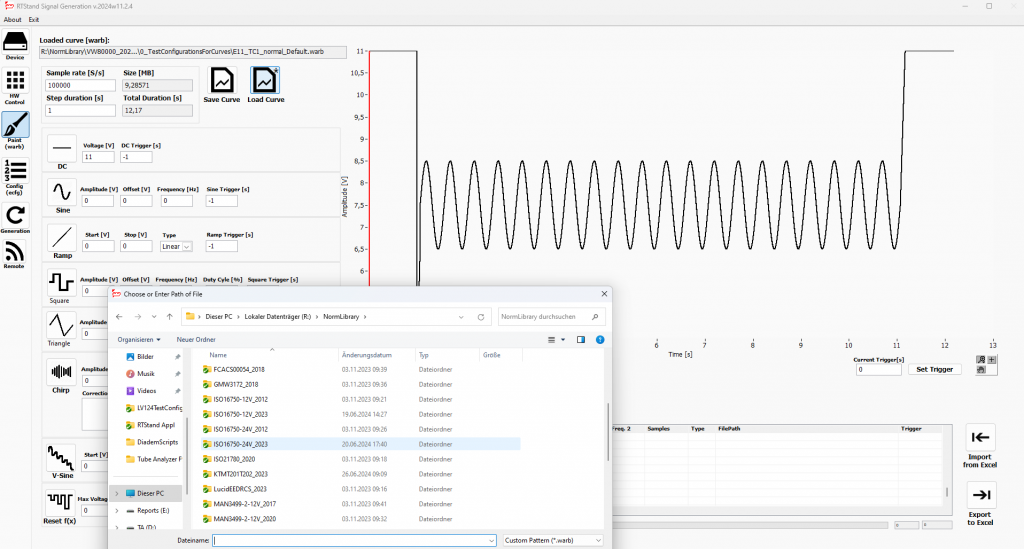

Figure 3. Extensive norm support for LV124 / LV148 testing

RTSTAND LV124 / LV148 TESTING HIGHLIGHTS

High performance components

The various types of tests, listed above, also bring the need to use a wide range of intelligent components, able to support all these requirements and also having the ability to work in fully automated environments.

Manufactured in Germany, these components support these various requirements and can be easily scaled up and down, according to customer needs.

RTStand Signal Generator

This component generates precise testing signals necessary for simulating real-world automotive conditions. Its comprehensive norm libraries for LV124 and LV148 ensure standardized and customizable test setups.

The device’s own software facilitates the automated execution of standard profiles, enabling consistent and repeatable testing procedures. It allows users to customize or create new testing profiles, adapting to specific testing needs.

Ultra-fast Interrupter

Designed for microsecond interruption tests, this device provides rapid switching capabilities crucial for evaluating the resilience of automotive components to power disruptions, supporting analog as well as bus interfaces up to automotive ethernet 1000base-T1 and GMSL.

Tube Analyzer

The Tube Analyzer measures voltage and current, in a wide range of channel layouts, with high precision, offering detailed data capture essential for in-depth analysis of test subjects. Its compact design ensures efficient and accurate monitoring.

Figure 4. Key devices for LV124 / LV148 testing

SOFTWARE AND INTEGRATION

Workflow toolchain

The RTStand LV124 / LV 148’s powerful software tool chain enables faster DUT integration and flexible reporting capabilities.

The Variant Handler tool simplifies the setup of new devices under test (DUTs), allowing quick configuration changes and ensuring efficient test preparations.

Customization without Programming

One of the key advantages highlighted in the training is the ability to customize the RTStand LV124 / LV148 system without any programming knowledge. This flexibility allows users to adapt the system to their specific testing requirements easily.

Climatic chamber integration

By interfacing various kinds of climatic chamber and cooler types (e.g. Weiss/Vötsch, Espec, CTS, Lauda etc.), RTStand LV124 / LV148 supports the climatic and communication requirements of all norms.

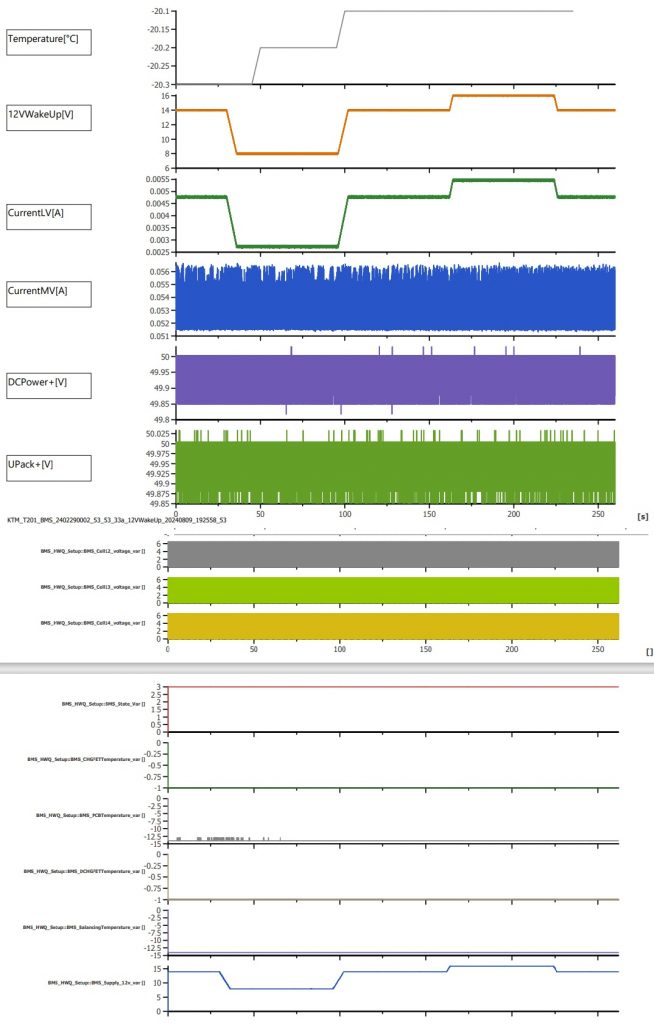

Automated reporting with CANoe / CANape log integration

RTStand LV124 / LV148 ’s software provides live views of ongoing tests, with features for monitoring and interactive feedback. The system also supports automated report generation offering detailed insights of the DUT behaviour. Due to the customizing options of the reporting, customers can create their own data displays for various purposes (internal, external, management or technical level insights).

By interfacing standard industry tools such as CANoe / CANape, time-synchronized analog and bus data (e.g. CAN, LIN, Ethernet etc.) can be displayed for a much faster and preciser analysis.

Figure 5. Customized PDF Report for LV124 / LV148 testing

MODULAR AND SCALABLE DESIGN

The modular design of the RTStand LV124 / LV148 system, allows for scalability and adaptability. Users can start with a basic configuration and expand as their testing needs grow, ensuring a future-proof investment.

If testing needs change over time, the customer can easily upgrade the system’s hardware for more or new interfaces, e.g. Automotive Ethernet 1000base-T1 or GMSL, thus optimizing budget spendings.

Moreover, the software platform is being continuously maintained. Started years ago on a Windows 7 platform, it now supports Windows 11 and the newest software tools in the industry. One of the main focuses at WKS is to support the customers for as long as needed, and the yearly updates insure up to date norm libraries, software tools and operating system migrations.

Figure 6. Various system layouts for LV124 / LV148 testing supporting up to 96 power lines and more than 14 CAN, LIN + 8 Automotive Ethernet 1000base-T1 / GMSL lines

CONCLUSION

The RTStand LV124 / LV148 testing system by WKS Informatik GmbH is a state-of-the-art solution for automotive component testing. Its compliance with a wide range of standards, coupled with its advanced automation and integration capabilities, makes it an indispensable tool for ensuring the reliability and efficiency of automotive components. By adopting RTStand LV124 / LV148, customers can significantly reduce testing times and costs, bringing high-quality products to market faster and maintaining a competitive edge in the automotive industry.

Moreover, through the continuous maintenance plans, customers receive the newest releases for LV124 / LV148 norms, as well as software improvements and integration capabilities for new communication interfaces, in order to support their developments for ECU generations to come.

For more information or to discuss your specific testing requirements, please contact us at:

- Web: wks-informatik.de / lv124-rtstand.com

- Email: contact@wks-informatik.de

References:

- All supported LV124/LV148 OEM norms and specifications

- WKS Norm Comparison Overview – https://www.wks-informatik.de/wp-content/uploads/DocumentDownloads/April2024/WKSInformatik_LV124_LV148_2024_v1_NormOverviewAndComparison.pdf

- WKS published documents – https://www.wks-informatik.de/en/published-documents/